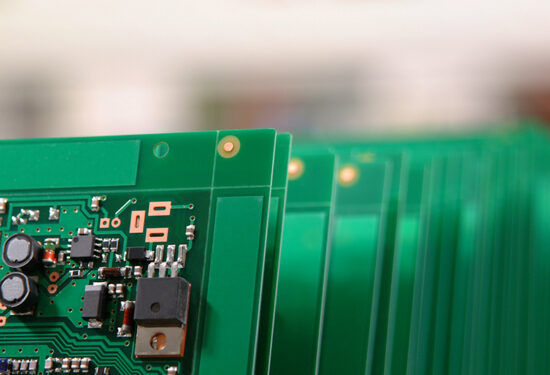

Electronics Manufacturing

M&M Automatic Products provides CNC machining services for a wide range of products in the electronics manufacturing industry. We are ISO 9001:2015 certified and uphold strict quality standards to ensure that every machined part meets your needs and tolerances. From the most precise connectors and sockets to durable electronics casings, heat sinks, screws, and much more, we can tackle a diverse array of electronics components. We specialize in short runs and small lot sizes, with typical runs between 50 and 100,000 pieces. In addition to CNC turning, milling, screw machines, and more, we also offer finishing services to help make your project run smoothly from start to finish.

We are:

- ISO 9001:2015 certified

- Expert machinists with 30 years of experience

- Specializing in runs between 50 and 100,000 pieces

- Experts in design, machining and finishing services

Our CNC Machines:

- Hardinge Talent 51 Turn/Mill Center with Bar Feeder (Max Barfed Bar Diameter @ 2″)

- Haas VF-2 machining centers with 5th axis capabilities ( max material size of 24L x 13W x10H )

- Haas VF-2SS machining centers with 4th axis capabilities ( max material size of 24L x 13W x10H )

- Haas TM-1 Tool Room Mill with 3 axis capabilities ( max material size of 24L x 8W x 6H )

- Haas ST-10 Mill/Turn Center with Bar Feeder (Max Barfed Bar Diameter @ 1-3/4”)

- Mori Seiki SL204SMC Main/Sub Mill/Turn Center with Bar Feeder (Max Barfed Bar Diameter @ 2-9/16”)

Our Screw Machines

- 9/16″ RA6 Acme Gridley

- 1″ RA6 Acme Gridley

- 1-1/4″ RA6 Acme Gridley

- 2-5/8″ RA6 Acme Gridley

- 1-5/8” 6-spindle Greenlee

- 2” 6-spindle Greenlee

Get a Quote for Your Electronics Components Project

Do you have questions about CNC machining for your electronics components? We’re happy to help.

Flexible, Fast, Precise

CNC machining offers fast, flexible construction in electronics manufacturing. While many other manufacturing technologies require hazardous chemicals or introduce structural defects, CNC machining makes it easy to precisely fabricate thousands of even the most delicate and complex pieces. With a wide range of materials, including carbon alloys, aluminum, brass, stainless steel, high nickel alloys, titanium alloys and plastics, we make it easy to construct lightweight, durable, intricate components to suit nearly any need. From consumer electronics to industrial controls, specialized electronics for vehicles and transit, cutting-edge prototypes and mainstays, our experienced team has the expertise and capabilities to build all types of components for the electronics industries.

In addition to fast, precise production, CNC machining also offers flexible development. With no tooling prior to production, and computer-aided manufacturing technology supporting development and design, it’s easy to make changes to your designs as needed. With over 30 years of machining and design experience, our team can also help you perfect your designs to make production more efficient and cost-effective.

Designing, Machining and Finishing

In addition to precision CNC machining services for all types of electronics components, we also offer design assistance and finishing services to help complete your project from start to finish. A few small changes to your design or fabrication process can help to save thousands of dollars across a full run. Our experts bring decades of experience to your project, and can help you perfect your design, raw materials, and process to save time and money. Once your designs are streamlined and your electronics components are ready for production, we use strict quality standards to ensure that tolerances are met. Finally, we provide a wide range of finishing services and logistical support to help complete your project smoothly. We offer anodizing, plating, grinding, finishing, assembly, warehousing, packaging and just-in-time delivery. Tell us about your needs and we’ll design a plan to deliver your components quickly and cost-effectively.

Our services include:

- CNC Machining

- CNC Milling

- CAD/CAM design assistance

- Anodizing

- Plating

- Grinding

- Finishing

- Assembly

- Warehousing

- Packaging

- Just-in-time delivery